Argo Tractors, technologies and investments for in-house manufactured tractors, globally competing in the market

An integrated production process: this is the strategic choice that drives the production of Argo Tractors, a major player in the tractor market, based in Fabbrico, Reggio Emilia (Italy) and owner of the McCormick brand, which has decided to manufacture in-house three of the four main tractor components – cabs, axles and drivelines – purchasing the engines from external suppliers.

“The decision to produce the vast majority of the components of our products in house – comments Paolo Fracassini, Supply Chain Manager of Argo Tractors – combined with the decision to focus on the production of tractors – rather than the entire full line of agricultural equipment – allows us to be competitive in the market place. We focus on an extremely advantageous way to improve cost control, high quality standards and a significant reduction in the time to market.”

Argo Tractors dedicates a specific plant to the production of the cabs. Located near the company headquarters in Fabbrico, it comprises an area of about 33,000 square metres, 10,000 of which covered, and employs workers and specialised technicians using the most advanced and robotised technologies and giving the plant an overall maximum production capacity of 105 units per day.

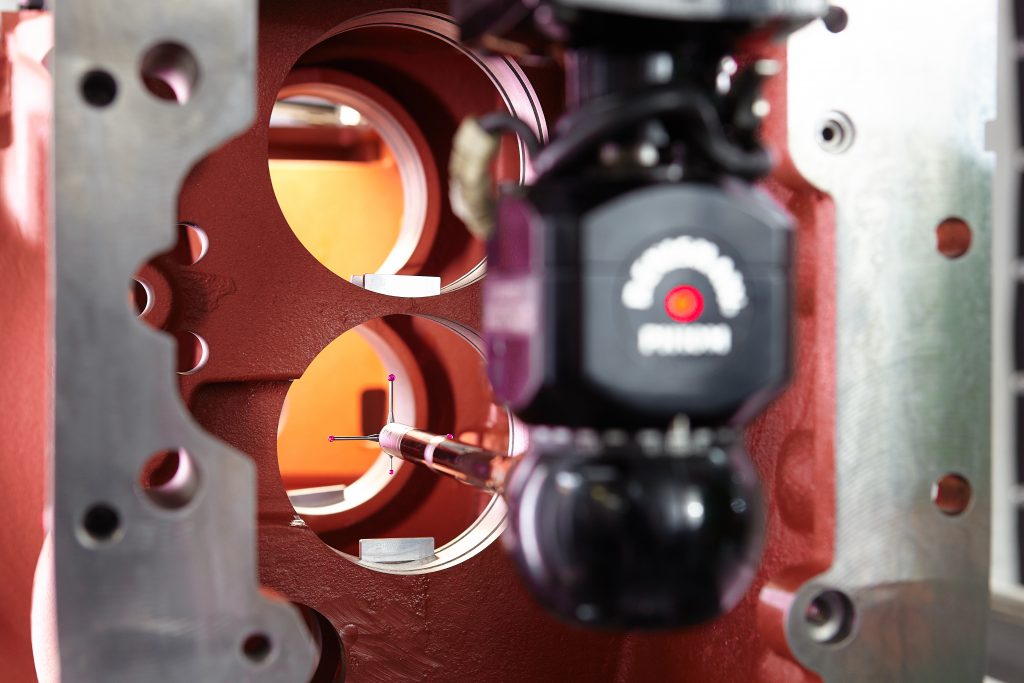

Another core function is the machining of the structural parts of the tractor driveline, such as the cast iron housing, the gearbox, the differentials, the rear hitches and the final drives, as well as the steel parts, i.e. gears and shafts. All machining operations are carried out with state-of-the-art Horizontal Numeric Centres, which are subject to a turnover that, in order to guarantee functionality and efficiency has led in the last years to the introduction of a large number of new machining centres, with annexed equipment and tools.

Driveline production is located in two Argo Tractors plants, one specifically dedicated to the processing of cast iron – generally carried out on multi-pallet HNCs, also based in Fabbrico – and the other one, in nearby San Martino in Rio, for the production of steel components thanks to NC machine tools.

“Thanks to this strategic approach we currently produce in-house about 65% of the tractors components average value – adds Mr Fracassini. This guarantees a high-quality standard of the final product. Moreover, company choice of constant technological renewal of the plants is based on Industry 4.0 concepts, as well as specialised and continuous training of our staff is a key factor of our success. Our strong commitment in innovation is represented by 5.5% annual turnover investment in R&D. All above mentioned, plus the attention given to the human factor, with a great sensitivity to environmental issues and customers’ needs.”